Problem

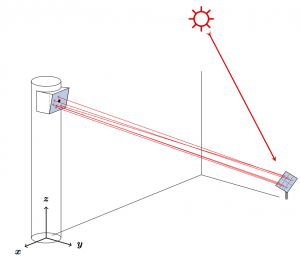

Among the renewable energy technologies, solar tower power plants are a promising option for power generation. Their basic technical idea is as follows: An array of adjustable mirrors, the heliostats is arranged around a tower with a receiver unit on top. By each heliostat sun light is reflected in direction of the receiver to heat up a fluid, e.g. thermal oil or molten salt. A heat exchanger transfers water into steam, such that the steam powers a turbine to generate electricity. Sizes of these power plants may vary from several hundreds to 100 thousand of heliostats.

Aiming strategies are used to reach an optimal flux distribution on the receiver surface. As a result, each heliostat is assigned to focus on a specific location on the receiver surface. Thus, to reach this goal, the heliostats need to be precisely calibrated.

Goals of this Lab

Within this project, a High-Precision Heliostat Calibration System is developed. We aim to use drones in a heliostat field. With a camera-based optical measurement system in combination with an accurate localization of the drone, the tracking angle of the heliostat can be determined.

Tasks

Within this lab several tasks need to be solved. Each will be solved by a group of two to three students:

- Concept: Work out a concept for a Heliostat Calibration System using drones. This concept includes the following sub-tasks.

- Central intelligence unit for the operation of drones: Communication flow (starting, flight route, positioning mode, measurement mode, drone state). Consider fault tolerance (what happens if drones or hubs are out of service?), safety protocols (loss of signal, low battery, windy weather conditions).

- Optimized Design: Development of a cost-optimized infrastructure of drone-hubs in the field. The number of drones, drone-hubs and their position in the field is optimized, considering safety constraints and hardware limitations (e.g. radio signal range or battery capacity). Extend the design for different modes of operation, e.g. cleaning, which sets different requirements to the drones.

- Flight operation of drones: Flight scheduling (trajectory and task planning), measure a heliostat four times a day.

- Positioning mode: What happens, if drone cannot find the heliostat? Low-resolution images.

- Measurement mode: Each drone is equipped with a camera (High-resolution). Extract the normal angle of a heliostat from a given image and position of the drone. What is the best angle of the camera? Should we use an optical zoom?

- Calibration mode: From 4 or more measurements (image and position at several instants of time) derive the alignment error of the heliostat. This is used for calibration.

- Hardware Interface: Communicate with camera, drone, radio transmission (wifi), laser-tracker,

- 3D Model for Simulation: Develop a simulation environment for all systems, which can generate images and evaluate them.

Contact

This project takes place in the Theory of Hybrid Systems (i2) research group headed by Prof. Dr. Erika Ábrahám. The project will be co-supervised by Pascal Richter and Stefan Schupp.